| Parameter Item | Specification | International Certification |

|---|---|---|

| Engine | Briggs & Stratton 25T2 Single-Cylinder Diesel Engine | ISO 8528-5 |

| Type | OHV Four-Stroke Air-Cooled, 420CC | EPA Phase III |

| Power | 13.5HP/3600rpm | SAE J1349 |

| Capacity | 350kg (772lbs) | ANSI B56.6 |

| Bucket | 0.15m³ (5.3cu.ft) | ISO 6016:2008 |

| Gradeability | 25° (Certified by ASTM D6473 Test) | – |

| Track | 180mm (7.1in) | NFPA T2.13.1 |

| Speed | 3km/h (1.86mph) | – |

| Dimensions | 2470×900×1300mm (97.2×35.4×51.2in) | ISO 286-2 |

Product Introduction

Analysis of Engineering Advantages | Crawler Self – Unloading Dump Truck | CE/ISO Dual Certification | All – Terrain Material Transfer Expert | Crawler Self – Unloading Dump Truck | 25° Gradeability | Global Warehouse Stock

1. Efficient Power System

- Briggs & Stratton 25T2 single – cylinder diesel engine (420CC displacement)

- 1L large – capacity oil sump (maintenance – free for 8 consecutive hours of operation)

- 12V electric start + 10A generator coil (-15℃ low – temperature adaptation)

2. All – Terrain Adaptation Design

- 180mm wide crawler tracks (ground contact pressure ≤ 25kPa)

- 65mm ground clearance (gravel terrain passability increased by 55%)

- Hydraulic rotation system (190° flexible steering angle)

3. Precise Material Control

- 100° hydraulic dump angle (error ± 2°)

- 255mm unloading ground clearance (compatible with standard hoppers)

- 15m³ standardized cargo box (for construction waste/feed transfer)

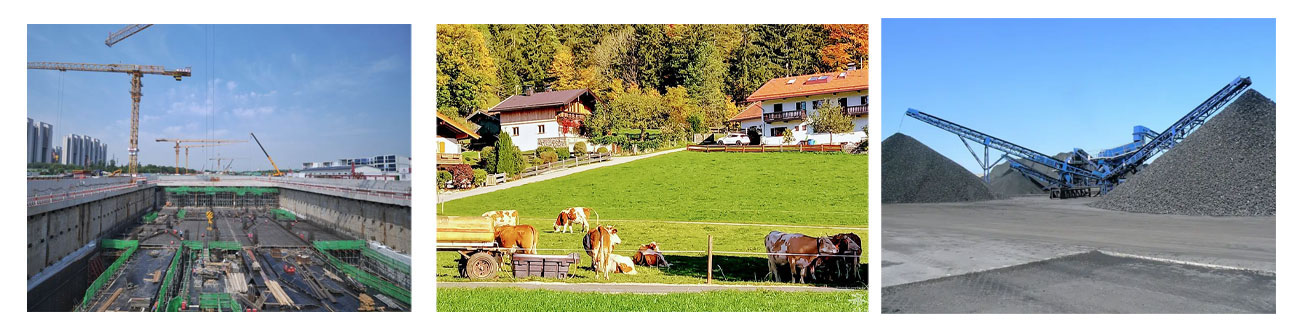

Global Application Scenarios

- Construction Sites

- Transports 2.5 tons of building materials in 1 hour (compatible with C30 concrete hoppers)

- 2470mm compact length for traversing narrow passages

- Agricultural Management

- Quick loading and unloading of silage (safe operating speed of 3km/h)

- Wetland crawler design (adhesion coefficient in swamps ≥ 0.7)

- Mining Operations

- Continuous operation on 25° steep slopes (certified by ASTM D6473)

- 350kg heavy – load capacity compatible with standard mining hoppers

Reviews

There are no reviews yet.